Air8 Scrubber Systems

The AiR8 Scrubber Strategy features the exclusive, proven and patented System REITHER™ Variable Throat Venturi Scrubber for sub-micron particles and variable gas flows. Using AiR8 scrubbing liquid this scrubber is efficient for removing acid mists, aerosols, particulate matter, and related odors. The AiR8 System REITHER™ Variable Throat Venturi Scrubber is easy to control, maintain, and delivers exceptionally high performance. Its small footprint, high efficiency, high reliability, and adjustable venturi throat (accommodating varying gas flow loading) makes this remarkable system a powerful and unique solution. Each system is constructed to meet the individual needs of the specific application. Materials of construction vary according to application. Fiberglass reinforced plastic (FRP), polypropylene, and polyvinyl chloride (PVC) materials are excellent for highly corrosive atmospheres. Coated carbon steel, various grades of stainless steel and other metal alloys are also available.

AiR8 Emission Control Systems are effective in handling toxic, hazardous, dusty and mixed gas streams such as:

- Acid mists — HCl, H2SO4, SO3, H3PO4, HF, NH3

- Salt aerosols — NH4Cl, NH4F

- Aluminum chloride and chlorine

- Metal oxides — Cu, Zn, Pb

- Fine dusts including pharmaceutical powders

- Fine mists — organic and alcohols

- Fumes — welding, production, solvent-based printing inks and paints

Benefits of Venturi Scrubbing

Of all the air pollution abatement technologies, wet scrubbing systems remain the most versatile and cost efficient. Venturi scrubbers are particularly effective at removing particles from 1 µm to 100 µm at very high efficiencies. At the submicron size, the principle of the venturi scrubber is to force the contact of the particle with fine water droplets. This is done by using a constricting orifice, creating a venturi throat that forces the intimate contact between the water and the particles or aerosol. Various designs of venturi scrubbers are available. The System REITHER™ Variable Throat Venturi Scrubber is the new generation of venturi scrubber.

Some of the advantages of the System REITHER™ scrubber include:

- Simple and compact design, able to connect with existing flue gas ducting;

- High removal efficiencies for sub-micron dusts and aerosols;

- Flexibility to handle any mass flow rate especially at smaller flows;

- High and constant reliability;

- Easy to control by simply using pressure drop;

- Ability to absorb and remove gaseous contaminants;

- Can handle corrosive streams through corrosion resistant material;

- Scalable design capability – systems can be built to handle a wide range of flow rates.

Removal efficiencies of greater than 99% are achievable

for particulate less than 3 um in diameter.

New advances in throat design have led to significant improvements in removal efficiencies, the ability to respond to variability in flow, and the ability to remove very small particles, aerosols and various gases.

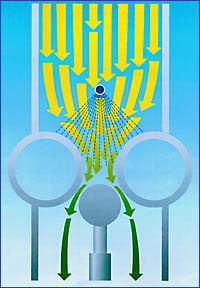

The principle of the design is illustrated in the figure shown at right. The gas stream enters the scrubber vessel, passes by the scrubber liquid spray heads, and is forced between two stationary cylinders into the middle region. A third cylindrical displacer on a lifting rod, creates two venturi throats, one on either side of the displacer cylinder. The vertical movement of the displacer allows the optimum throat width to be set according to the contaminant loading of the gas stream, for maximum efficiency.

The System REITHER™ Variable Throat Venturi Scrubber features several important innovations. The scrubbing solution is sprayed at low pressure but, due to the high sheer effect of the throat on the gas stream – with velocities between 50 and 150 m/sec. – the liquid aerosols are further atomized into a mist of very fine droplets possessing huge surface area. This is the key to the performance of this design. Compression in the venturi throat, high gas acceleration in the throat, and the high relative velocity between particles and scrubbing aerosols combine to provide for excellent opportunity and probability for contact and, therefore, separation efficiencies with this venturi scrubber. The variable throat features eliminates dependency on precise theoretical forecasting of scrubber performance conditions, by allowing the venturi to be “tuned” under actual conditions, and then adjusted whenever conditions change.

AiR 8 emission control solutions include:

- Scrubbers

- Packed Absorption Towers

- Tray Scrubbers

- Cyclones

- Demisters

Suitable for:

- Rendering plants

- Pulp and paper plants

- Food and beverage production

- Printing and paint plants

- Other odorous industrial processes.

Every AiR8 Solution is engineered for optimal performance

We have the engineering expertise to design and install a system for you, regardless of how demanding your performance requirements may be. The AiR8 System Design Team is committed to making choices that are best for your application. Each situation is unique and is treated as such.

Details such as air pressure, temperature, humidity, pH levels, and other variables can influence operations and efficacy — minor adjustments can increase efficiencies, or reduce costs. After installation, our analysts look for ways to further optimize your system for cost, product usage and effectiveness.